The latest version of Rolls-Royce stabilisation systems adds the potential for ice class ships to benefit from the company’s Stabilisation-at-Rest (SAR) concept.

The SAR system, incorporated to both the Aquarius and Neptune ranges of Rolls-Royce retractable stabilisers, employs active fin control technology and advanced hydrodynamic design to deliver higher levels of roll reduction when the vessel is at rest, and also maintaining stabilisation performance whilst underway.

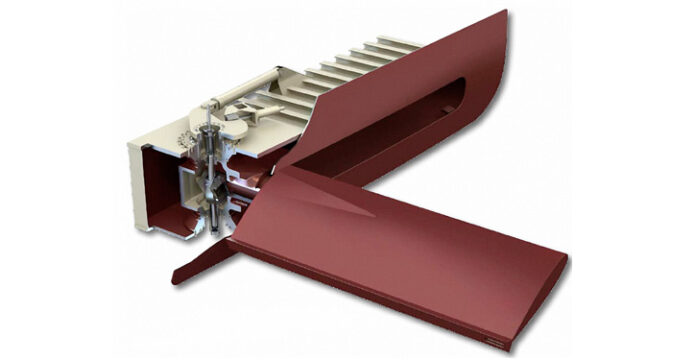

In the new design, the stabiliser fins can be fully retracted into the custom-designed fin box, so there are no protrusions from the hull form, ensuring safe navigation through ice.

The new design has a reduced fin area and optimised lower fin angle which meet the stabilisation performance requirements. The new design also reduces dynamic drag when deployed underway which leads to lower fuel costs. The stabiliser fin incorporates the proven Rolls-Royce trailing edge design which eliminates vibration and noise.

Martin Cunningham, Managing Director, Rolls-Royce Motion Control Dunfermline, said: “The one-piece fin construction offers simple maintenance, reducing through-life cost. The fin shape is designed to improve zero speed performance, as more chord is behind the fin centreline.”

“This is achieved because the ice class SAR system is based on the well-established Rolls-Royce Aquarius and Neptune retractable stabilisers. Both initial and operational costs are minimised due to the units being easily installed, the fin box custom-designed to exactly match the ship’s hull profile, small hull opening and a simple reliable design.”

Recognising that the Rolls-Royce ice class SAR stabilisers are likely to be employed on vessels sailing in environmentally sensitive areas, a special quad seal arrangement ensures minimal risk of leakage, and the machinery is fully compatible with a wide range of EALs (environmentally acceptable lubricants).

“The sealing arrangement and compatibility with EALs mean the ice class SAR systems meet the requirements for VGP Permit vessels, while the low drag results in less fuel being burned, which also benefits the environment,” adds Cunningham.