RKLAB engineers believe its self-pressurizing injector will bring several benefits to engine efficiency.

Details emerging from a Swiss company may signal a radical technology development that could provide a diesel emissions-reduction solution while reducing cost and complexity. Central to a project now being conducted by Lucerne-based RKLAB AG is a self-pressurizing fuel injector designed to provide the potential to reduce exhaust emissions sufficiently to eliminate the need for exhaust aftertreatment. It also obviates the need for an external high pressure pump, saving cost and weight. The aim is to productionize the injector technology for high-volume applications, explains diesel powertrain specialist Prof. Bernard Challen, a technical advisor to RKLAB.

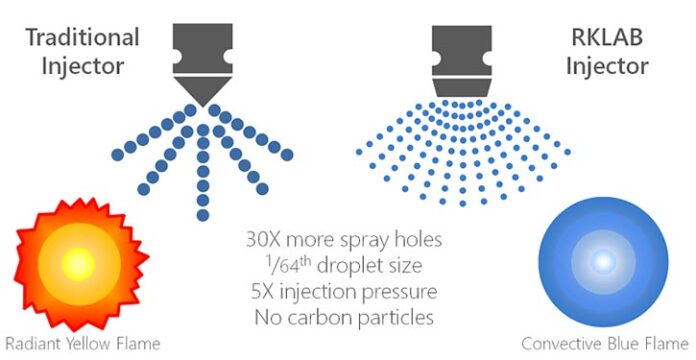

“The RK injector generates much higher pressures than any current system and can deliver the fuel through a large number of minute holes (up to 180), compared to six or eight in a current conventional injector,” Challen explained. “This creates smaller fuel droplets, better mixing and cooler, more complete combustion, leading to reduced NOx, fewer particulates and greater fuel economy.

“It also removes the need for an external high pressure pump, reducing system cost and improving mechanical efficiency,” he said.

Driven by cylinder pressure

The RK designation stands for Ron Kukler, a combustion engineer who has spent many years developing “green” diesel solutions. The RK injector is a development of established technology but with the potential to apply modern processes and manufacturing techniques to achieve compact and robust volume production solutions.

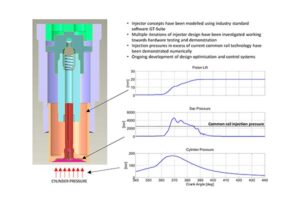

Although RKLAB is headquartered in Switzerland, development work is under way in the U.K. The engineering consultancies Ricardo, and Powertrain Technology Ltd. (PTL), working with Prof. Challen, are helping with development. Simulation, using Gamma Technologies’ GT-Suite software, has been used to clarify priority areas for validation and make physical testing more efficient.

The continuing development and popularity of diesels in the face of hybrids and boosted- downsized gasoline engines has resulted in greatly reduced CO2 emissions and fuel consumption. But that success also has raised public health and regulatory concerns about diesel NOx and particulate emissions. Vehicle OEMs are challenged to reduce the cost and complexity of current aftertreatment systems, which often compromise fuel efficiency and performance.

To help meet this challenge, focus has been placed on fuel injection system development. Injection pressures have been steadily increasing, from 1800 bar (26,000 psi) about a decade ago towards 3000 bar (43,500 psi). The next-generation systems will deliver fuel through a greater number of smaller orifices with more sophisticated rate shaping involving multiple injection events. The use of exhaust gas recirculation (EGR) and increasingly sophisticated exhaust aftertreatment, mainly selective catalytic reduction (SCR) and diesel particulate filters (DPFs), has also contributed, although downsides include system complexity, which makes long-term reliability harder to achieve, and increased cost to the consumer.

Cost has long been a negative for automotive diesel power, much of it down to the fuel delivery system and its associated hardware.

Prof. Challen explains that with RKLAB’s RK injector, fuel delivery pressure is driven by cylinder pressure. “It is continuously self-adjusting, which provides inherent, stepless rate-shaping of the injector pulse and helps reduce the peak rate of pressure rise during the combustion event,” he noted. “This leads to lower structural loads on the engine (reduced by up to 60% in tests) and improves NVH, reducing the characteristic diesel sound.”

The natural feedback process within the RK injector, taking its signal from the pressure in the combustion chamber, “means the combustion curve of the fuel dictates the rate at which fuel is added, optimizing the rate of injection to eliminate either over or under fuelling and adapting to different fuel characteristics,” Prof. Challen said.

The injector can also be controlled using solenoid valves, designed to provide the same (or improved) diagnostic tools as a conventional injector, able to monitor and control the combustion process.

The shape of the fuel spray pattern is also different to conventional systems. Instead of forming a conical surface, the spray can take the form of a flat disc which makes both swirl and a traditional combustion bowl unnecessary, Prof. Challen explained. He said this creates new possibilities for piston, combustion chamber and port design that could lead to lighter, more compact engines with better gas exchange.

The finer atomization produced by the RK injector also reduces the delay between injection and combustion, a fundamental constraint on the maximum useful rpm for a diesel. Prof. Challen believes this could help bring diesel and gasoline engine architecture much closer together: “The ability to extend the speed range while using a lighter cylinder block structure and a more compact piston design makes the potential for common hardware greater,” he said.

Details and development steps

The project started in 2014 and prototype engines tested so far include a range of diesels from single cylinder to large truck engines. The RK technology has also been trialed on a number of gasoline engines converted to diesel operation, taking advantage of the lower peak cylinder pressure operation of the technology.

The achievement of cost-effective manufacture of high-quality surface finishes to close tolerances has been central to the development. Until the next raft of patent protection is in place, RKLAB is keeping the internal details of the injector confidential. But engineers involved with the project confirm that the injector uses an electro-hydraulic multiplier to magnify pressure, and high speed, high flow valving to control fuel delivery.

The development priority is now to achieve controllability and monitoring to satisfy global standards for on-board diagnostics (OBD), to enable the technology to be commercialized.

A detailed multi-domain simulation approach is being undertaken by PTL to define the details of the injector design. The effective use of modeling helps to reduce the number of hardware iterations and shortens the development effort, which is critical.

Phenomena like solenoid electromagnetic operation, hydraulic spool valve behavior, fuel compressibility and cavitation, clearance changes with pressure as well as the effect of fuel heating by exposure of the injector plunger to hot combustion gases, all need to be considered. Optimized combustion chamber shapes are to be developed using combustion CFD before validation with fired engine tests, engineers involved with the RKLAB project noted.