Introduced as the fuel optimised Mark 10 engines

The ever valid requirement of ship operators is to obtain the lowest total operational costs, and especially the lowest possible specific fuel oil consumption at any load, and under the prevailing operating conditions.

MAN Energy Solutions said recently “that we are pursuing further design optimisations that benefit our customers and the environment.” Therefore, the German engine builder introduced the Mark 10 version of the G-type 80 and 60-bore engines, i.e. the G80ME-C10.5 and the G60ME-C10.5.

Together with the other existing Mark 10 engines, these engines will be ready for the newbuilding market when it expectedly picks up after 2020, when the fuel oil situation is expected to be more clear, and the EEDI will require lower CO2 emissions. The optimised Mark 10 includes the necessary engine design and performance changes to suit the relevant ship types and their required optimum SMCR.

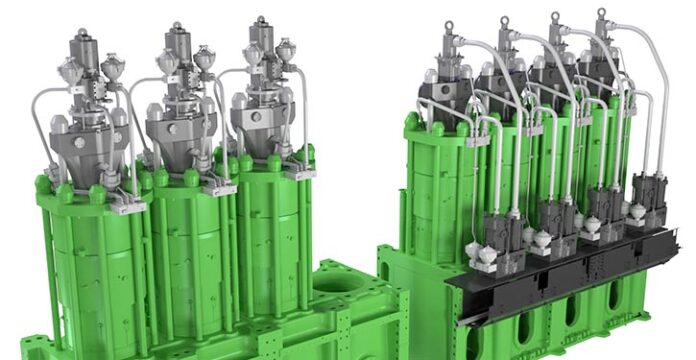

MAN ES: “For some years now, our primary R&D target has been to develop the next generation of our ME platform. During this time, the goal has been to utilise the full potential of the ME engine concept by reducing the complexity of the hydraulic system and increase system performance; the new TCEV and FBIV technologies have been developed within this scope.”

The design initiative delivers a specific weight reduction of up to 10% per kW, and also accommodates a higher max output, which also contributes to a reduction in fuel consumption and consequently CO2 reduction.

G80

The G80ME-C10.5 utilises the full Mark 10 design platform introduced with the G90ME-C10.5.

The main result will be an approximately 5% weight reduction for a 7 cylinder engine and the SFOC will be reduced by 2 g/kWh over the whole load range. The weight reduction is the result of a reduced cylinder distance enabled by the flexrod connecting rod, the flexible main bearing support, and the optimised cylinder frame. To cater for the increased maximum pressure, the G90ME-C10.5 incorporates the latest design of combustion chamber components adopted from the G95ME-C10.5, the most potent engine in MAN’s low-speed offering (featuring max 6.870 kW per cyl.)

For a VLCC where, as an example, a seven-cylinder G80ME-C10.5 has been nominated as the propulsion installation, and at a specified maximum continuous rating(SMCR) of 22,500kW, MAN calculates that the daily consumption at 100% load will be 86.3t, compared with 87.4t for the engine in its Mark 9 layout(G80ME-C9.5). Pre-supposing a US$500 per tonne price tag for 0.5% very low sulphur fuel oil(VLSFO), this would translate into a US$531 per day fuel cost saving – and not to forget a 2,6 to CO2 reduction.

G60

The G60ME-C10.5 will have a reduced SFOC of 2.6 to 3.6 g/kWh depending on load and tuning methods. The design is largely similar to the G60ME-C9.5, with the same outline, footprint, cylinder distance, and height of structural parts, to minimise the necessary changes in production and for ship installation. However, the uprated combustion pressures require a review of the material, structure, and dimensions of moving parts and bearings as well as of the combustion chamber parts.

For a 2,500TEU container vessel, with a 6G60ME-C10.5 main engine at an SMCR of 12,400kW, the company indicates a 42.2t/day daily fuel oil consumption at 90% load, as opposed to 43t/day for the Mark 9 version. This would result in a US$410 daily saving on the basis of 0.5% VLSFO priced at US$500/to.

The first three models of the Mark 10 generation were announced in September 2016, as the G90ME-C10, S60ME-C10, and S70ME-C10 types, and were followed by the G95ME-C10. In each case, the latest variants have the C10.5 suffix. From the outset, the declared intention was to eventually upgrade all S- and G-engines to the Mark 10 platform.