MAN ES developes ME-GI engine further

What happens if one cylinder unit fails during operation on gas mode? In this case all cylinder units will continue to work on diesel fuel. But that’s not what the customer wants. According to MAN ES they have therefore made further developments on the ME-GI engine with the primary objective of the ME-GI Mk. 2 project to increase competitiveness by performance improvements and cost optimisation of the existing engine.

Gas cylinder cut-out

In order to increase the availability for gas operation on ME-GI engines, MAN ES says that they have developed a new feature called gas cylinder cut-out. Gas cylinder cut-out allows the operator to switch from gas operation to diesel operation on a single cylinder, if there is a failure, while the remaining cylinders maintain operation on gas. This will be able to cover some of the potential failures on the gas injection system in a safe way without compromising operation on gas. The feature has been requested by some owners targeting the increased availability of gas operation and, at the same time, with limited efforts by the crew.

In the current ME-GI Mk. 1 concept, a single failure on the gas injection system will stop any operation on gas on all cylinders, which means that the engine automatically will switch over to diesel operation on all cylinders and purge the engine free of gas. In the ME-GI Mk. 2 concept, it is possible to cut out failing cylinders individually. The gas cylinder cut-out feature also makes it possible to cut out a misfiring cylinder in case of, for example, failures on combustion chamber components still operating the remaining cylinders on gas, which will further improve the gas availability for the ME-GI engines .

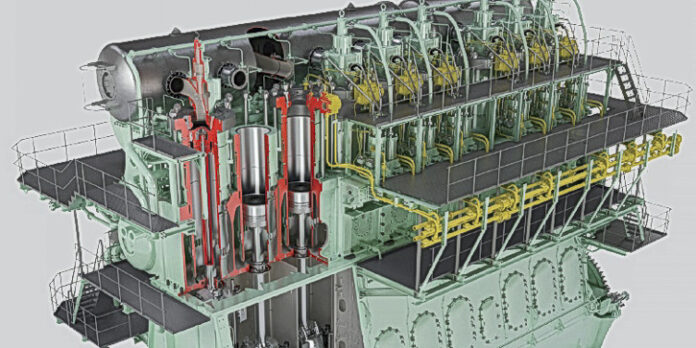

ME-GI Mk. 2 engine design

A number of new features are introduced with the target to reduce engine manufacturing costs and at the same time introduce solutions that will reduce the installation costs for the shipyard and ease of maintenance for the vessel crews.

The blow-off pipe is omitted, and half the chain pipes are therefore no longer needed, which reduces the number of engine components significantly. As a further consequence of omitting the blow-off pipe, the installation of a gas return pipe on the vessel is also eliminated.

In order to improve the durability of the engine, several pipes are removed from the top of the cylinder cover and replaced by internal channels in the cylinder cover, thereby improving the reliability and durability of the ME-GI engine, A new gas injection valve (GIV) Mk. 2 is designed for the in-cover piping with sealings in the cover, very similar to the sealings known from the FBIV design. The GIV Mk. 2 is easier to maintain, mainly due to the segregation of the actuator part and the injection part, thereby reducing maintenance costs.

The leak test of the outer double-wall piping is automated and controlled by the ME-GI engine control system (ECS), as is known from ME-LGIM and ME-LGIP engines. This test ensures that the double-wall ventilation system is working properly before gas operation is enabled.

ME-GI systems installation costs

The removal of the blow-off pipe is the most significant design change in the ME-GI Mk. 2 concept. It reduces the installation work for the yards and results in fewer components on the engine and the gas valve train (GVT).

Even though the safety concept is changed with ME-GI Mk. 2, the safe operation of the ME-GI engine will be fully maintained.