The Norwegian explorer cruise line, Hurtigruten, is to build its two new expedition ships, with an option for two more, using a new and environmentally sustainable hybrid technology from Rolls-Royce. In fact, MS ROALD AMUNDSEN and MS FRIDTJOF NANSEN about to be constructed at Kleven Yard in Norway will be packed with innovative Rolls-Royce solutions.

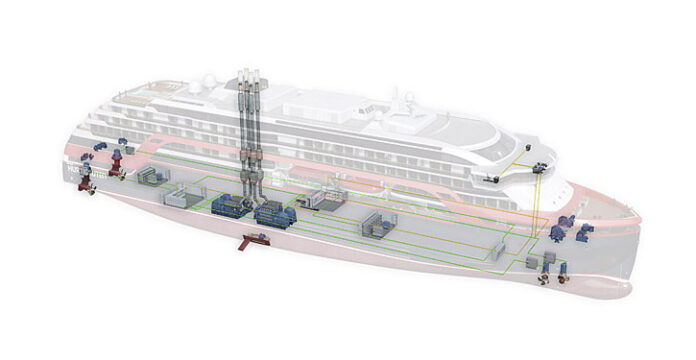

Hurtigruten announced that the two vessels are specially constructed for voyages in polar waters, which means they feature a strengthened hull and propellers for traversing ice. They will have 265 cabins for 530 passengers. With dimensions of 140 metres in length, breadth 23.6 metres, height 29 metres the vessels have a draft of 5.3 metres. MS ROALD AMUNDSEN and MS FRIDTJOF NANSEN are adapted for the service route along the Norwegian coast line. In addition to the hybrid power solution, the vessels will have the latest of automation and control systems, including the Rolls-Royce Unified bridge, the first delivery of two azipull propellers using permanent magnet technology, two large tunnel thrusters, stabilisers, four engines, winches and power electric systems. And of course the Rolls-Royce ship design.

A hybrid sea journey

The hybrid technology for MS ROALD AMUNDSEN and MS FRIDTJOF NANSEN is planned for delivery in two phases. In phase one, auxiliary accumulator power will provide large reductions in fuel consumption related to “peak shaving”. In an optional phase two larger energy storage systems can be installed, enabling the possibility of fully electric sailing across longer distances and over longer periods of time. This propulsion will be used when sailing into fjords, at port and in vulnerable areas.

Reduction of 3.000 tons CO2 per year

The decision to invest in a hybrid solution is an important milestone in Hurtigruten’s goal of sailing fully electric expeditionary ships in the Arctic and Antarctic. The technology, in combination with the construction of the hull and effective use of electricity on board, will reduce the fuel consumption by approximately 20 percent and CO2-emissions from the ships with 20 percent. This amounts to more than 3.000 metric tons of CO2 per year. “A passenger ship requires enormous amounts of energy to operate, and so far, there have been no technologies able to fulfil the requirements of a fully electric Hurtigruten ship. Hurtigruten’s new ships will probably be the first in the world,” said Daniel Skjeldam.

Electric propellers

Another innovation to be installed on both the vessels are main propulsion thrusters that use integrated permanent magnet (PM) technology instead of being powered by separate propulsion motors. Over the last two years, Rolls-Royce has launched a range of propulsion and deck machinery equipment driven by PM. From 2017 a new Azipull model will be on offer, and this is the product specified as the main propeller units on board Hurtigruten.

Azipull thrusters with pulling propeller and streamlined underwater skeg have proved highly popular propulsion units since they were introduced in 2003. Over four hundred and fifty units have been manufactured by Rolls-Royce (in Ulsteinvik, Norway) to date. With the introduction of electric drive through the use of permanent magnets, a proven Rolls-Royce technology is ensured a prolonged life according to SVP Propulsion Knut Eilert Røsvik: “We expect to see a shift from mechanical to electrical propulsion systems, and we are well positioned for this shift. We have invested in PM technology for more than ten years, and already have a lot of experience with it.”

The PM motor provides a very high efficiency over a wide speed range and reduces the space required in the thruster room. The propulsion system is well qualified for ships with ice class demand. Combined with the proven high propulsive and hydrodynamic efficiency of the azipull, this will be a winning combination.

Engine efficiency

As part of the hybrid power solutions to the new explorer vessels for Hurtigruten the newest diesel engines will be installed, the Bergen B33:45. According to RRPS, this medium speed engine has been chosen since its launch in 2014 by a variety of owners and yards for a range of ship designs, with 50 engines now delivered or on order. The engine offers 20 per cent increased power compared to its predecessor, delivering the same output with fewer cylinders. This lowers the costs through the engine’s lifecycle, and also allows for smaller engine rooms on board. The engine meets the international environment requirements for IMO NOx Tier III with support from a SCR system (Selective Catalytic Reduction System). These four engines in combination with the use of accumulators, comprise the cornerstones of the innovative hybrid solution onboard Hurtigruten.

Complete control

The captain and his team at the ship’s bridge, will literally have Rolls-Royce innovations in their hands. Ship control systems has developed fast over the last decade, and the number of screens, wires handlers and equipment for the operators onboard increased in parallel. Rolls-Royce has addressed this, and developed common control systems and a new Unified Bridge solution to clean up the clutter and design more user-friendly bridge and control stations for the crew. Ultimately, the result is a safer and more efficient working environment. The Unified Bridge represents a complete redesign of the ship bridge environment, including consoles, levers and software interfaces. It is said to be the most innovative bridge design available on the market today.

The Rolls-Royce supply package

The complete supply package of Rolls-Royce consists of: Four Bergen Diesel B33:45 main generating sets, each with scrubber systems; a high efficient accumulator system; the propulsion system comprises two Azimuth Thrusters – Azipull, with permanent magnet motor, and two tunnel thrusters; a remote control system and stabilizers of type Aquarius 100; a dynamic positioning system (DP0); ACON integrated automation system, including ACON Connect and ACON Energy; RRPS Unified Bridge including chairs, consoles and auxiliary bridge control; Rolls-Royce Power Electric System, technology including generators, motors, switchboards and a Power Management System; as well as mooring winches and cable lifter units of electric frequency converter and not to forget the design, basic design and detailed engineering.