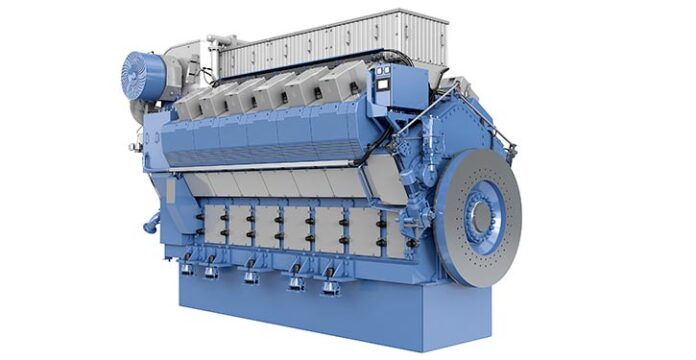

Rolls-Royce has recently launched a V-Line version of its highly successful B33:45 engine series. At 600 kW per cylinder the new design delivers 20% more power than the B32:40, in a compact design allowing more power in the same footprint as its predecessor.

The new V12 is the first variant in the new V-series, where a V16 and a V20 will follow, to address a bigger portion of the marine and land market. Typical marine applications will be larger fishing vessels, drilling units, heavy lift and construction vessels as well as medium sized cruise and passenger, cargo and tanker vessels.

The V12 engine, delivering 7.2 MW, is designed for both propulsion with fixed or CP propellers or as a generator set. One hundred percent of the power can be taken out of either end of the crankshaft. For generator drive the engine runs at either 720rpm (60Hz) or 750rpm (50 Hz) and for direct propulsion at between 450 and 750rpm on propeller law. At 750rpm the fuel consumption at 100% load is 176g/kWh, and on propeller law specific consumption is 175g/kWh at 85% load.

The engine is designed for invisible smoke at low load and to comply with Tier II requirements with no exhaust after treatment and Tier III with Selective Catalytic Reactor (SCR). To ensure low emission levels and optimum thermal efficiency throughout the power range, variable inlet valve timing is used to optimise both fuel economy as well as premium transient response. The engine is designed for liquid fuels according to ISO 8217: 2010 including MDO/MGO.

The cranktrain has been adapted to suit the different loading patterns of a V engine. Pump line nozzle fuel injection is standard, as customer research has shown that they like simple and known technology giving robust and trouble-free engines with competitive fuel consumption. However, a common rail option is also planned. The engine series also features the option ‘cylinder bypassed’, employed for optimised low load performance.

A modularised design makes servicing the engine easier. Both the In-line and V-series are designed for up to 30,000 running hours between major overhaul when operating at average loads within a specified window, enabled by dynamic service counter. This feature is a part of the Human Machine Interface system and the Ship Intelligence offerings currently being introduced by Rolls-Royce.

The resilient mounting system has been simplified, and allows variable speed generating sets for premium fuel economy and lowest possible emissions. Furthermore, this eliminates the need for welding on board during installation saving time for the ship yard and costs for customers. The pipe connections to the built on pumps have been standardized and framed as a part of the front end module enhancing operational lifetime of bellows and connectors.

Thor Humerfelt, Rolls-Royce, Head of Engineering – Bergen said: “This V-engine series completes the B33:45-engine family and gives our customers freedom to select their optimum power choice in the range between 3.6 MW and up to 12 MW. This will give them an excellent opportunity to reduce life cycle costs.”

The Bergen B33:45 In-Line diesel engine was introduced at SMM, Hamburg in September 2014. Available with six, eight or nine cylinders in line, close to sixty engines have been sold to date, says the engine manufacturer.

According to Rolls Royce has this engine series been chosen by a variety of owners and yards for a range of ship designs and applications, including fishing vessels, a seabed mining vessel and two unique cargo transfer vessels, medium sized cruise vessels, and research vessels such as RSS Sir David Attenborough.

The first vessel equipped with the B33:45, was the trawler “Holmøy” which successfully entered service in April 2016. The lead engine has logged more than 8,000 running hours in service.